Honeycomb cardboard combines lightweight design with exceptional strength, offering a sustainable alternative to traditional packaging materials. Its unique structure ensures durability while using 100% recycled content, making it both eco-friendly and cost-effective. Ideal for packaging, furniture, and creative projects, this versatile material meets practical needs without sacrificing environmental responsibility. Discover how honeycomb cardboard delivers strength and sustainability in one smart solution.

Comprehensive Overview of Honeycomb Cardboard

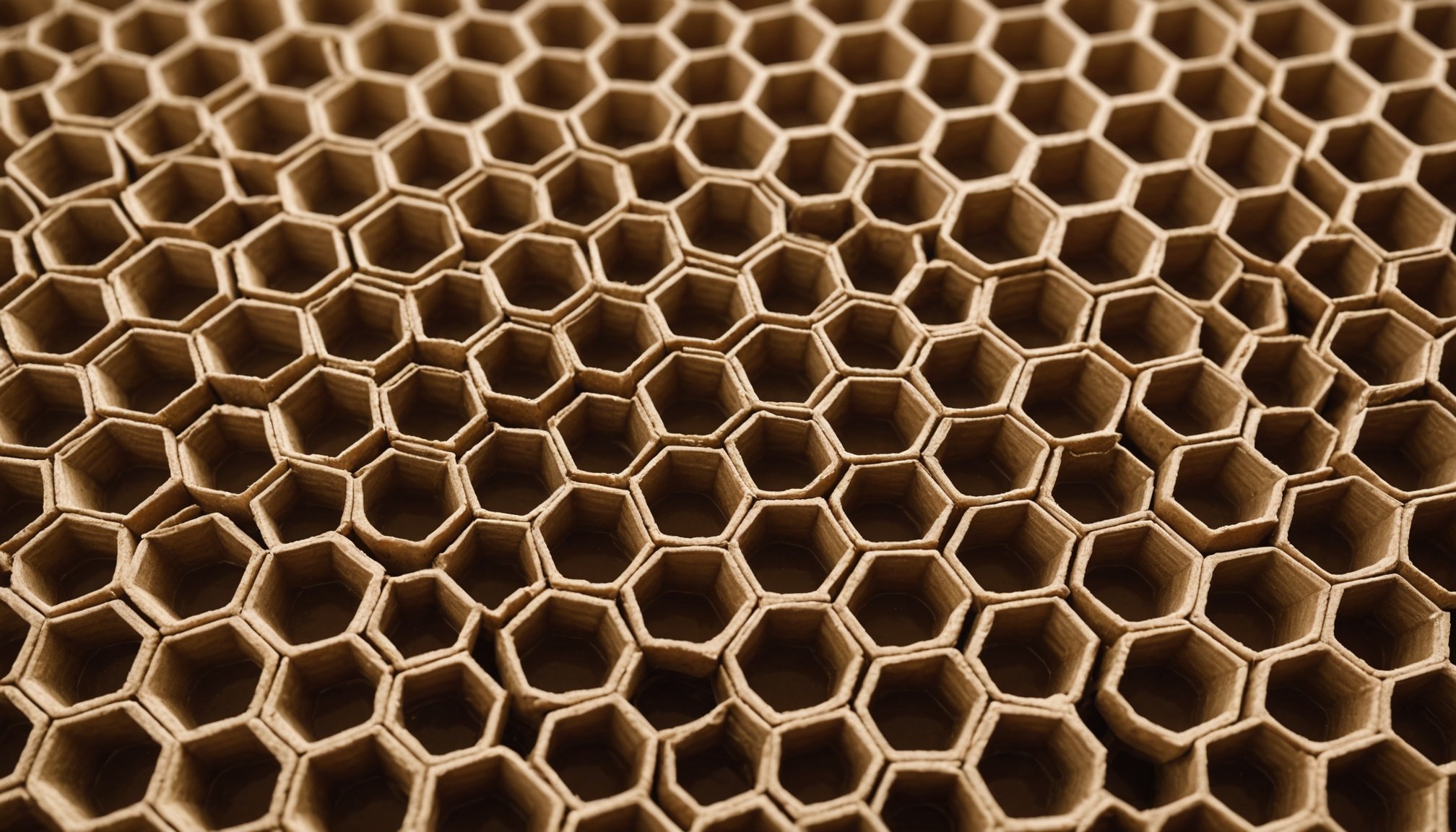

Lightweight and durable honeycomb cardboard features a hexagonal core sandwiched between laminated surfaces, offering notable strength and rigidity while remaining lightweight. This structure, frequently used in eco-friendly packaging materials, maximizes strength-to-weight ratio and supports various modeling, printing, and crafting applications.

Also read : What strategies are UK firms using to enhance global competitiveness?

Its eco-friendly benefits are driven by its composition of 100% recycled materials, which makes it highly recyclable and biodegradable. Additionally, honeycomb cardboard is heat resistant up to 80°C and can be easily cut, enabling quick customization and precise fabrication.

Use of honeycomb core panels for packaging provides a sustainable solution that lowers environmental impact without sacrificing durability. This versatile material is suitable for creating panels, blocks, and pads—ideal for protective packaging, furniture, and industrial applications. To explore more about this sustainable packaging option, visit the page: lightweight and durable honeycomb cardboard.

In the same genre : What Challenges Are UK Businesses Facing in the Current Economy?

Structural Properties and Manufacturing of Honeycomb Cardboard

Composition and Core Design

Honeycomb panels for packaging rely on a core crafted from virgin Kraft or recycled paper, formed into a hexagonal cardboard honeycomb structure. This configuration maximizes honeycomb core strength properties while keeping the material lightweight. The thickness can start at 1 mm for decorative panels and extend up to 50 mm for load-bearing applications such as cardboard honeycomb for pallets or furniture. The core’s geometry and material directly influence high strength cardboard panels: smaller hexagonal cells provide greater compression resistance, resulting in panels that outperform traditional solid cardboard in many scenarios.

Manufacturing Techniques and Customization

The honeycomb manufacturing process begins with the assembly of the honeycomb paper core, followed by lamination between kraft or white paper layers to create finished honeycomb cardboard sheet suppliers’ panels. After pressing and cutting, panels are customizable in thickness and dimension, essential for applications requiring honeycomb core panels with bespoke specifications. This flexibility means lightweight structural panels can be produced in bulk or tailored for unique packaging and insulation purposes.

Durability and Strength Attributes

Panels achieve compression resistance exceeding 70 PSI and stack easily without deformation, confirming robust honeycomb core strength properties. Weather resistance up to 80°C expands industrial uses of honeycomb panels for packaging and construction. Compared to foam core panels, these high strength cardboard panels deliver eco-friendly, durable performance for demanding environments.

Applications and Benefits of Honeycomb Cardboard in Industries

Packaging and Shipping Protection

Honeycomb panels for packaging are widely utilized as pads, cradles, and boxes for safeguarding fragile goods such as glass, electronics, and artwork. The cardboard honeycomb structure enables these panels to absorb shocks and maintain rigidity, addressing the issue of product shifting during transport and minimizing damage risk. Because honeycomb cardboard uses lightweight materials, shipping costs are reduced without sacrificing protection. Easy adaptation to unique dimensions supports custom-fit packaging, making honeycomb panels for packaging ideal for diverse product shapes and sizes.

Furniture and Display Solutions

Innovative furniture manufacturers use honeycomb panels for packaging as the basis for beds, desks, and modular displays. The honeycomb cardboard structure, with its high strength-to-weight ratio, guarantees both durability and easy handling. For visual merchandising, honeycomb cardboard uses include signage and promotional displays, as its printable surface and strong build enhance brand visibility while supporting sustainability goals. The reuse of honeycomb panels for packaging further benefits eco-focused businesses—panels can be reassembled or repurposed, contributing to sustainable packaging solutions.

Automotive and Construction Uses

In vehicles and buildings, the lightweight but robust honeycomb panels for packaging provide essential structural support. Honeycomb cardboard uses range from interior panels and insulation in the automotive industry to lightweight support elements and insulation boards in construction. These sustainable packaging solutions offer major advantages—reduced total structure weight, enhanced strength, and improved environmental credentials—all thanks to the reliable cardboard honeycomb structure.

Sourcing, Suppliers, and Buying Considerations for Honeycomb Cardboard

Honeycomb cardboard sheets dimensions in the UK range extensively, matching needs from crafts to industrial packaging. Standard honeycomb cardboard panels often measure around 2×1.2 meters, with thicknesses from 8mm up to 50mm, but many honeycomb cardboard sheet suppliers can offer custom sizes and bulk quantities.

Reliable suppliers, like those leading in the honeycomb cardboard supplier UK market, prioritize eco-friendly packaging materials—using 100% recycled paper and ensuring recyclable packaging materials for all honeycomb panels for packaging. When selecting the right source, always verify environmental certifications such as FSC® or PEFC™; these confirm a commitment to sustainable packaging solutions.

“Where to buy honeycomb cardboard near me” is a frequent consideration for UK businesses. Big-box stores like Home Depot occasionally stock smaller sizes, but specialized honeycomb cardboard sheet suppliers typically provide a broader range of honeycomb cardboard sheets dimensions and options for custom honeycomb cardboard solutions. For industrial clients, look for honeycomb cardboard packaging UK suppliers offering fast turnaround, flexible quantities, and cost efficiency in honeycomb packaging—key traits for meeting commercial needs sustainably and reliably.

Body

Utilizing a cardboard honeycomb structure delivers superior strength-to-weight performance for eco-friendly packaging materials. This design, with its hexagonal cells, optimizes load distribution and achieves higher compressive strength than traditional solid cardboard—making honeycomb panels for packaging a preferred choice in demanding logistics environments.

Cardboard honeycomb sheets dimensions range significantly, enabling businesses to match their lightweight structural panels to diverse requirements. Thickness options extend from as thin as 1 mm to robust selections at 50 mm, supporting applications from parcel reinforcement to heavy-duty crate lining. These panels ensure product protection without adding unnecessary weight or cost.

The honeycomb core panels applications are extensive. In packaging, lightweight structural panels safeguard fragile goods while remaining recyclable and cost-efficient. Industries make use of custom honeycomb cardboard solutions for shipping, storage, and even retail displays, thanks to their adaptability and strength. For those looking to scale sustainability efforts, this technology supports a closed-loop system by supporting recycling and reuse across the supply chain.

In summary, adopting cardboard honeycomb structure technologies ensures both environmental improvement and optimal product security, with adaptable options for varied industry needs.